VISIONLITH - Wheel Alignment for cars and vans up to 3.5t.

High resolution cameras and 3D technology provide quick and accurate measurement of vehicle dimensions and offer a number of procedures not available in infrared technology (CCD).

Movable camera beam makes VISIONLITH suitable for scissor lift, four-column lift and pit.

Automatic target tracking system is an additional advantage. The cameras automatically follow the lifted car. Mobile cabinet allows free movement between measuring stations. No calibration is needed.

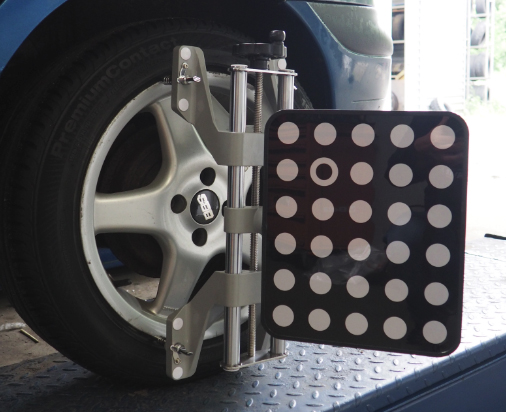

3D technology. High resolution cameras take pictures of targets and on this basis the system calculates the angles in vehicle suspension.

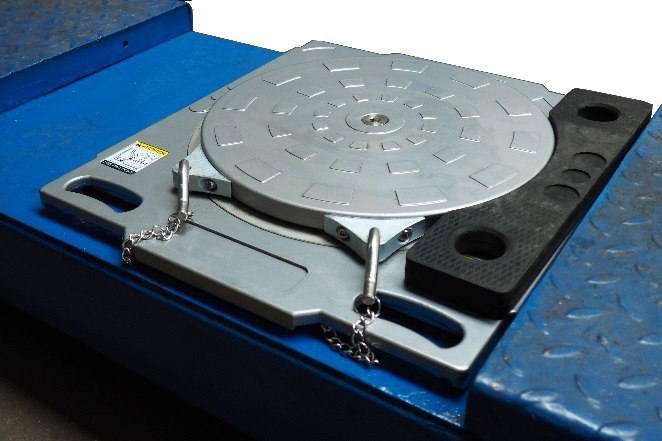

Passive targets attached to aluminum wheel clamps. The system quickly calculates the camber angle. No battery charging, no tangled power cables.

Automatic cameras height adjustment. The system tracks the targets when raising / lowering the car on lift and cameras adjust their height automatically.

Autodata database with control points diagrams is the heart of VISIONLITH.

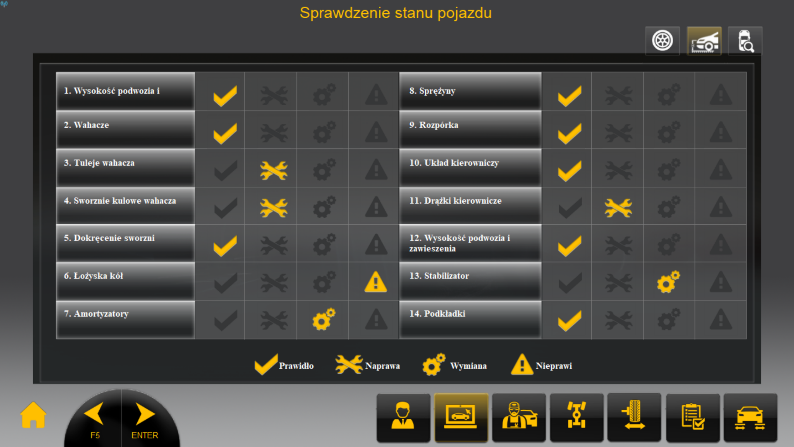

Tyres, suspension and vehicle condition inspection report. Before starting the measurement the operator can prepare an inspection report with information about vehicle technical condition. The report can be printed for the customer.

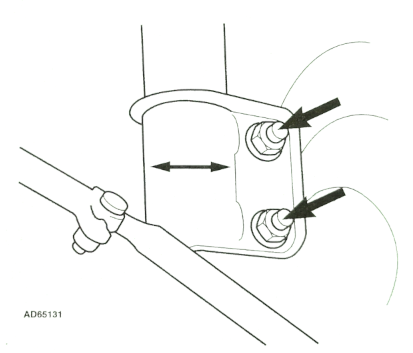

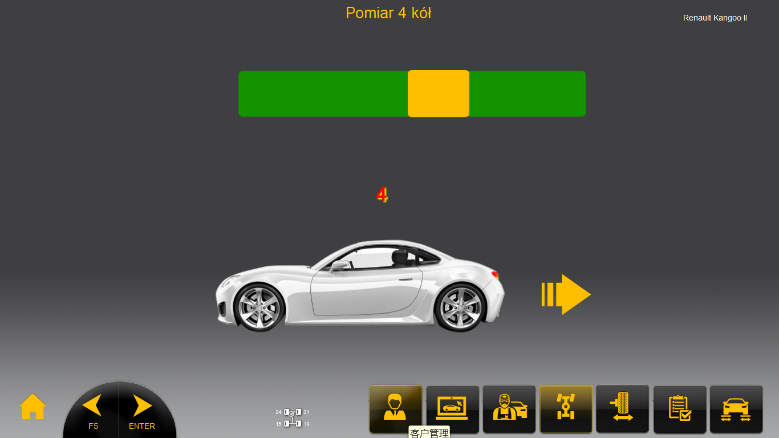

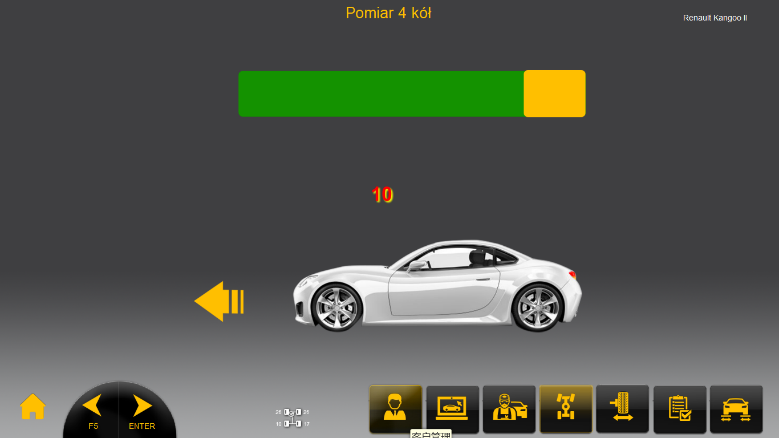

Quick wheel runout compensation. By rolling the car backwards and forwards.

Caster angle measurement can be made at 10° or 20° turning of the wheels. During the measurement you can measure the maximum steering angle as well.

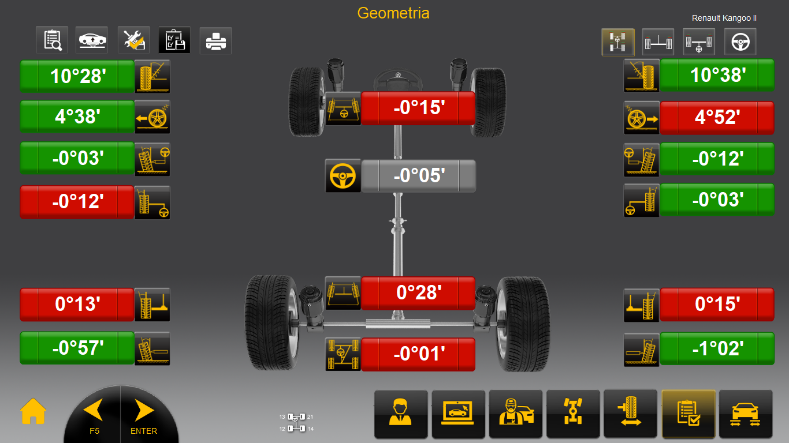

Clear measurement results. After the measurement the results can be shown as complete or limited to preview the rear axle, front axle, caster.

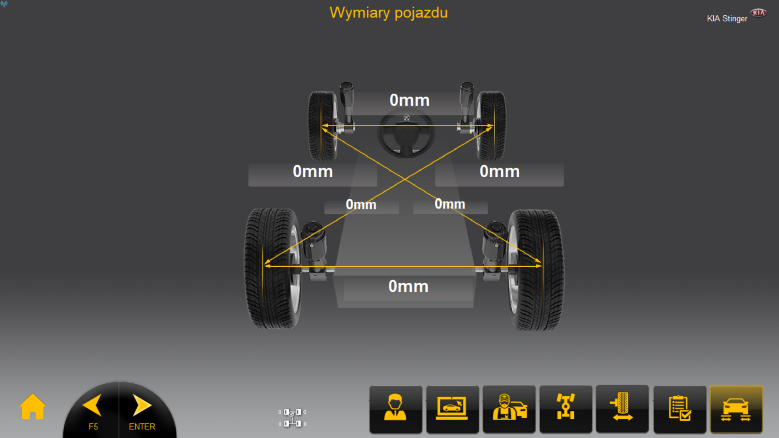

Vehicle length and diagonals. The software allows you to control the axis offset relative to each other.

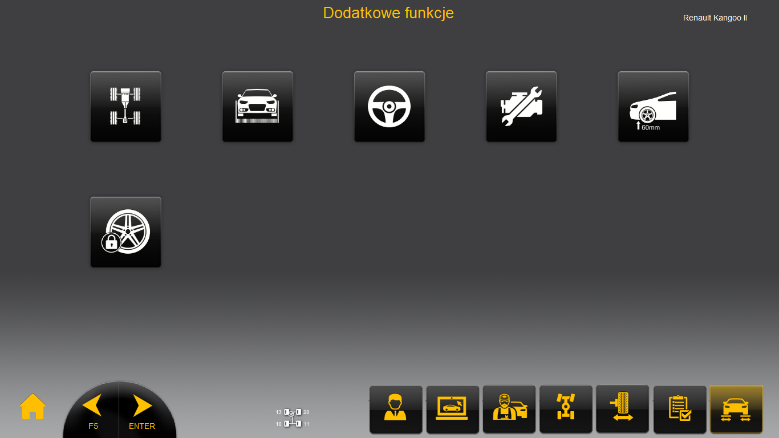

Additional functions:

Technical data:

| Cameras, pcs | 2 |

| Toe range | ± 20º |

| Camber range | ± 10º |

| Caster range | ± 20º |

| Supply | 230V, 50Hz |

| Rim clamping range | 10 – 24’’ |